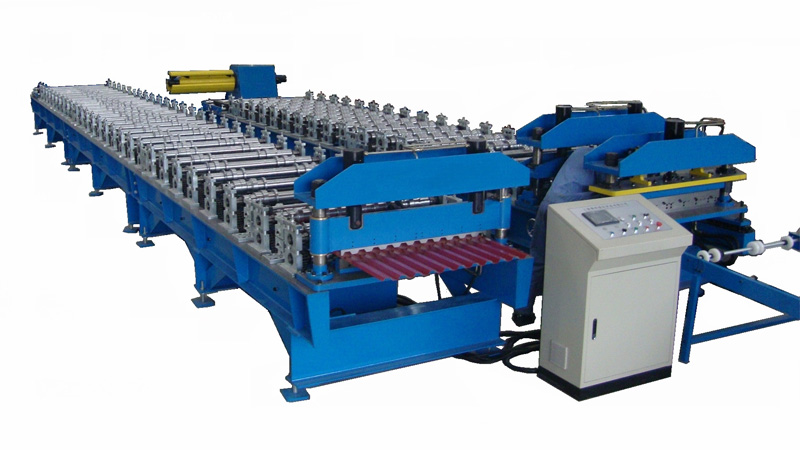

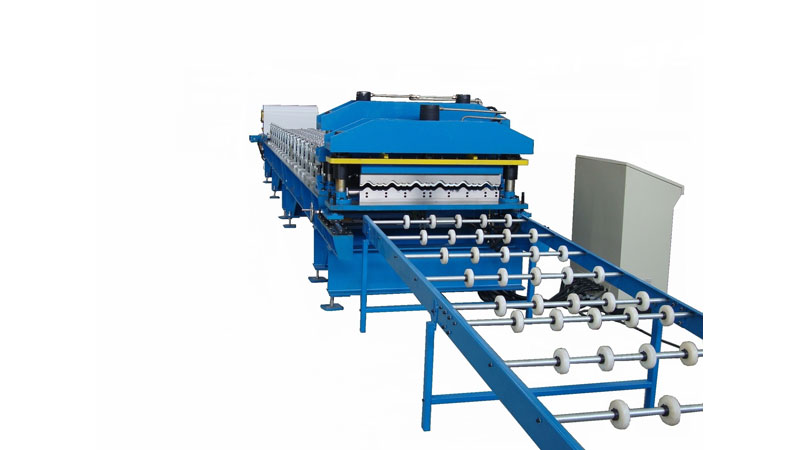

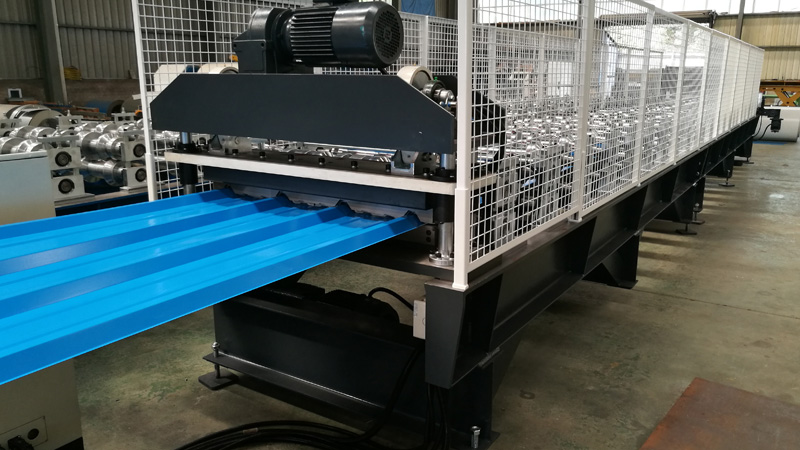

Hangzhou Rolling and forming Technology Co., Ltd. Produced roof Panel and wallboard Rolling and forming Machine Dignity and elegancy, Beautiful and New, Flat appearance, even corrugation, High Utilization rate, High Strength, High Automation of Production, low cost.En todos los fabricantes de rodillo de techo, ofrecemos todo tipo de rodillo de pared estándar y no estándar: máquina de fabricación de azulejos de techo, rodillo de techo de caja, rodillo de cartón corrugado, rodillo de techo;Máquina de fabricación de azulejos de vidrio, máquina de fabricación de azulejos de techo de alta velocidad, máquina de fabricación de azulejos de techo metálico, máquina de enrollado de placas de plata, máquina de enrollado de placas de plata, máquina de enrollado de Canaletas, máquina de conformación de placas de enclavamiento, etc.

| Metal Decoiler | Cantilevered Type Hydraulic Expandingz Hydraulic Releasing With Light control Separate Hydraulic station and control |

| Guiding device | Adopting a guiding bar and sliding block to control the width and position of the steel sheet. The sheet is guided in the correct position and runs to the roll forming equipment. |

| Roll Forming System | 1. Roof rolling machine frame: welding structure with blasting treatment 2. The roller is made by high-quality no.45 steel with hard chrome-painted 3. Roller inner supporting structure type: guiding column 4. Planetary gear speed reducer motor-driven, back/forward roller driven by a chain, part of upper/lower rollers driven by gear. 5. Adjust the screw bar manually to adjust the distance between upper/lower rollers for different thicknesses of the sheet. |

| Punching die and Cutting Device | 1. The cutting blade material of roof making machine is Cr12 with quenched treatment, there is no material wasted. 2. The power of cutting is provided by a Hydraulic station. |

| Product Supporter | To support the finished panels manually and the length of each piece is 2 meters, two pieces. |

| Electrical Control System | With PLC control and frequency speed adjusting technology to realize the automatic production |

| Hydraulic Station | 1. Provide power to cutting. 2. Adopts separated hydraulic station 3. Main valve adopts China brand. |

Nuestra línea de producción de máquinas de conformación de rodillos produce placas trapezoidales, placas onduladas, placas de costura vertical, azulejos de techo metálico, placas AG, placas PBR, cubiertas de cresta, etc.También diseñamos y fabricamos líneas de rodadura de acuerdo a las necesidades de los clientes.Sección.

Tenemos algunas locomotoras populares.Si el cliente necesita personalizar la máquina, tomará unos 45 días.

Podemos diseñar y fabricar máquinas de fabricación de Tejas metálicas de acuerdo a las necesidades de los clientes.Su propia sección.Si el cliente necesita personalizar la máquina, tomará unos 45 días.

Podemos diseñar y fabricar líneas de laminación de aluminio.

En general, el espesor del techo / pared oscila entre 0,23 mm y 1 mm.Si los clientes quieren hacer paneles más gruesos, también podemos diseñar máquinas;